Filtration

Filtration is employed to separate a dispersion according to the size of particles. The filtered mixture is applied on a filter made of a suitable porous substance. Particles smaller than the pores can cross the filter and get into the filtrate while larger particles are trapped on the surface of the filter.

Filter[edit | edit source]

Filters are made of various materials. Filtering papers belong to the most traditional ones – these are special unsized papers of a suitable porosity. Gauze, cotton wool, glass wool and other materials can be used to filter out rough particles. On the other hand, speciality mambranes made for example of celulose acetate, PVDF, nylon or other materials are used for separation of smaller particles.

Arrangement of Filtration[edit | edit source]

Filtering solution through filters with very small pores is time consuming. The process is faster if the pressure of filtered liquid is incresed (high-pressure filtration) or the filtrate is aspirated (vacuum filtration).

The most simple example of high-pressure filtration is use of syringe filters. The filtered mixture is aspirated to a syringe. Encapsulated membrane filter is attached to it. Overpressure is reached with the piston of the syringe.

Syringe filters are used e.g. for sterilising solutions like eye drops in pharmacies.

A similar principle is employed in centrifugation filters. In this case, the filtration unit resembles a test-tube or micro test-tube. Vhen the compartment for sample is filled with the filtered mixture, the whole unit is placed into a centrifuge. The centrifugation force speeds up the process of filtration.

Vacuum filtration is, on the other hand, based on aspirating the filtrate. In the classical arrangement, the filtration membrane os placed on the Büchner funnel that is attached to a vacuum flask. Disposable filtration units for vacuum filtration made of a suitable plast are available today as well.

|

|

|

| Syringe filters (from [1]) | Centrifugation filter (from [2]) | Vacuum filtration (from [3]) |

Filtering through a Paper Filter[edit | edit source]

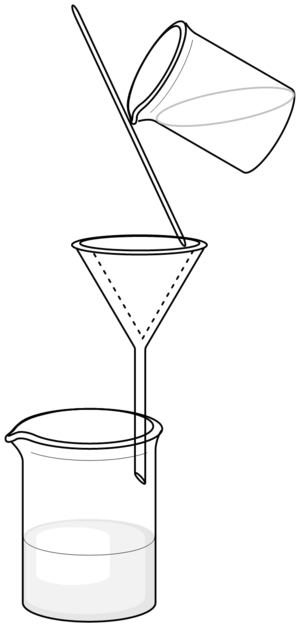

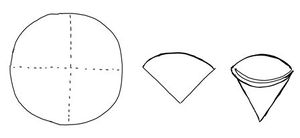

- A circle of a filter paper is folded to quarters. Then it is unfolded so that it forms a cup.

- The cup is placed into a funnel. Frequently, it should be moistened (usually with distilled water).

- During filtration, the stem of the funnel should touch a wall of the collecting container. The filtered mixture is poured onto the triple layer of the filter paper.

- The filtered mixture must be added slowly. It must never reach the top of the filtration paper or even overflow it.

Links[edit | edit source]

Related articles[edit | edit source]

References[edit | edit source]

- ↑ Labicom. Filtrace [online]. [cit. 2009-10-26]. <http://www.labicom.cz/default.aspx?section=142>.

- ↑ National Scientific. Centrifugal Filters [online]. [cit. 2009-10-26]. <http://www.nationalscientific.com>.

- ↑ Dartmouth College. ChemLab. Vacuum Filtration [online]. [cit. 2009-10-26]. <http://www.dartmouth.edu/~chemlab/techniques/vfiltration.html>.